Do You Know How a Sewing Machine Works?

by William Sanders

The sewing machine was a groundbreaking invention that changed the textile and fashion industry. Whereas crafting a cloth with hand sewing would take days after days to finish, the task has now become facile and quick only due to the use of a sewing machine.

Sewing machines deserve a big thank from us for all the fancy clothes we have in the wardrobe. Not only does it make the job easier, but also it allows intricacies and styles in our everyday attire.

But have you ever wondered how such machines work? If you don't know yet, you are in the right place. This article will explain the different processes of a sewing machine and give you a clear idea of how it functions.

Contents

Key Parts of a Sewing Machine

A sewing machine consists of numerous little and big parts that serve different purposes to facilitate the work of sewing. A number of most important key parts and their functions are mentioned below.

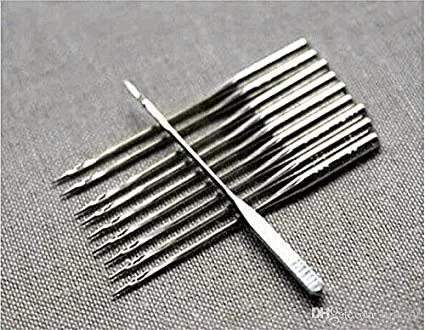

Needle

The needle is, apparently, one of the essential tools for a sewing machine. A needle's job is to pierce and move up & down through the fabric to make stitches on it with a thread connected in.

However, the type of needle used in a sewing machine is different from the type we use while hand sewing. The basic difference is that the ones used for machines have their eyes at the sharp end, while it is totally opposite with the regular ones, which have the eyes at their back.

Also, all needles are not of the same type and size. They come with a difference based on various styles of sewing and fabric.

Handwheel

A handwheel is used to lift the needle up or to pull it down.

Bobbin and Shuttle

A bobbin is basically a small spool of thread that stays inside another tool called the shuttle. Bobbin, along with the shuttle, is placed inside the machine right below where the needle reaches while making stitches. The thread winds out from the bobbin as the machine functions.

Press Foot

A press foot is a flat tool that holds the fabric in place while the stitching occurs. It is placed across the needle with a little gap between its two toes, through which the needle moves up and down. There is a press foot lifter, using which the foot can be lifted up and pressed down.

Feed Dog

Feed Dog is a metal bar with teeth, located under the press foot. It functions to move the fabric with every stitch being made and ensures equal length between the stitches. There is a reverse lever that can be used to switch the feed dog's moving in the opposite direction.

Stitch Selector

In modern-day machines, there is a stitch selector, which you can use to choose the type of stitch you want to put. It also lets you regulate the width and length of stitches you are willing to make. However, old fashioned machines do not have this tool, and all work of it is done manually on them.

Thread Feed

Every sewing machine has a thread feed. The thread feed, which is also called a spool pin, is a thin metal rod that holds the spool, where the thread comes from. It allows the thread to roll out freely and ultimately reach the needle through different loops.

This helps the thread to avoid getting tangled up and maintains its tension so that it delivers to the needle smoothly.

How the Sewing Machine Works

The main process of sewing in a sewing machine can be divided into three parts. The needle mechanism, the bobbin & shuttle mechanism, and the feed dog mechanism altogether do their respective parts and carry out the stitching finely on the fabric. How the three mechanisms work is described below -

-

Needle Mechanism

The most important mechanism of the three is the needle's one. It's so simple how it does its job! The thread is passed through the needle's eyes, which is at the bottom end of it. With the machine running, the needle, along with the thread swiftly paces in an upward and downward motion through the pressure foot and the feed dog.

Then, the shard end of the needle pierces through the fabric, pushing the connecting thread with it. The needle then reaches down to the bobbin and connects its thread to the other line of thread coming out from the bobbin.

Bobbin and Shuttle Mechanism

The bobbin and shuttle together work in synchronization with the needle's mechanism to make the stitch. And the bobbin is located within the shuttle, with a line of thread released from it.

While the needle keeps it moving up and down, the shuttle's work is to hook the thread coming from the needle and pull it down to wind it over to the other thread coming from the bobbin. Both the threads of bobbin and needle interact and develop a tight stitch on the fabric, while the needle pulls its thread back up.

Then, the shuttle repeats this process in a loop and finalizes the work by creating stitches one after another.

Feed Dog Mechanism

Now the feed dog's work is to pass the fabric steadily and smoothly over itself and to equalize the length of stitches. It works by motioning upward and forward simultaneously, in a synchronized pace with the needle and the shuttle.

The upward move dabs against the fabric which also gets backed by the press foot from the opposite side, and the forward move slides the fabric away, while and after the stitch is made. The craftsperson aids the process by holding the fabric securely and pushing it softly along the way.

With all of the three mechanisms working together incoherence to one another, the stitches are made on the fabric. If even one of the mechanisms fails to work in synchronization, it will result in dropped stitches or even lead to stitches not being made.

Below is an animated visualization of how the mechanisms work in a sewing process to make it easier for you to perceive.

Final Words on Sewing Machine

It is not a must to know how a sewing machine works for people who sew. But having a notion of the mechanisms will definitely help in some problems, especially while troubleshooting the machine.

Also, people who are new to sewing will have an idea of what to expect. So, if you are a sewer, by now, you already know the secrets behind the nice stitches you make.

|

|

|

|

|

|

|

|

About William Sanders

William Sanders was born and raised in California. After receiving his Master’s degree in information science from San Diego State University, he started working as a city councilor. In his spare time, William enjoys playing best-selling MMORPG games such as World of Warcraft and Fnal Fantasy, where he often takes on the role of guild leader with hundreds of players collaborating for success under his leadership. William is also a regular contributor to some popular magazines such as San Jose Mercury News, Gleanster Research, and Palmgear.

Leave a Reply

You can get FREE Gifts. Or latest Free phones here.

Disable Ad block to reveal all the info. Once done, hit a button below

|

|

|

|