How Is a 100% Cotton T-shirt Made ?

by Alice Davis

T-shirt is a popular form of apparel among people of all ages. No matter wherever you are, you will see someone wearing a t-shirt having a quote or image on it.

Most comfortable t-shirts are made of cotton. There are also t-shirts made of cotton and polyester blend, cotton and linen blend. However, in terms of quality and comfortability, nothing comes close to 100% cotton made t-shirts.

The fabric to use while making t-shirts depends on designers' preferences, budget, and the purpose of usage. That's why there are different types of cotton made shirts.

If you wonder how a cotton t-shirt is made or want to know about the process, this article will enrich your knowledge regarding this matter.

Contents

Some Basic Things Related to T-shirts

Most cotton t-shirts that are available in the market are made of 100% cotton. There are some manufacturers who use organically grown cotton along with natural dyes to make t-shirts for environmentalists.

The neckband serves the purpose of providing support to the entire fabric while giving it an even finished appearance. Most neckbands are of 1×1 inch rib knits, although some high-quality ones come with 2×2 rib knits.

A t-shirt also includes materials such as tape binding, stiff pieces. Binding secure the necklines as well as shoulder seams, and also protects from tearing apart if there is too much tension. Some t-shirts have elastic at the shoulder seams to make them flexible.

Another essential element in any garment is the thread. A single t-shirt includes several types and colors of thread. Most manufacturers use white thread for seaming. If a t-shirt design includes any visible topstitching, then a color thread is used that blends with the garment itself.

The final procedure for making a t-shirt includes trimming and braiding.

Summary of How a 100% Cotton TShirt is Made

- Cotton is a natural fiber that comes from the cotton plant

- The cotton plant is harvested and the cotton fibers are extracted

- The cotton fibers are cleaned and spun into yarn

- The yarn is knitted or woven into fabric

- The fabric is dyed and printed

- The finished product - a 100% cotton t-shirt!

How Is a 100% Cotton T-shirt Made in Detail ?

It's a long process. I tried to break down every single step with minimal description.

Collecting Cotton Balls

It all starts in the cotton fields. Cotton balls are collected from the field using a gin. Then, the usable cotton is separated from the chaff and seeds through a mechanical process.

For more efficient work, most cotton gins these days use saws and multiple powered cleaning cylinders that require less intensive labor while ensuring high productivity.

Looming

The bales of cotton fibers then go through the comb and blend processes. Here, cotton fibers are blended, carded, and combed in a different facility. The fibers turn into loose strands through the carding process. Later on, a picking machine takes off the cotton for knitting on a looming machine.

Wet Processing

At this stage, the fabric is treated with chemicals and heat to give it the final appearance and touch. The fabric is required to go through several processes such as bleaching, printing, and dyeing. Furthermore, the inspection for grey textile is performed here, as well.

This entire stage can be divided into three parts; preparation, coloration, and finishing. Finally, the cotton fabric gets the desired softness and coloring and is ready to proceed to the next step.

Styling and Cutting

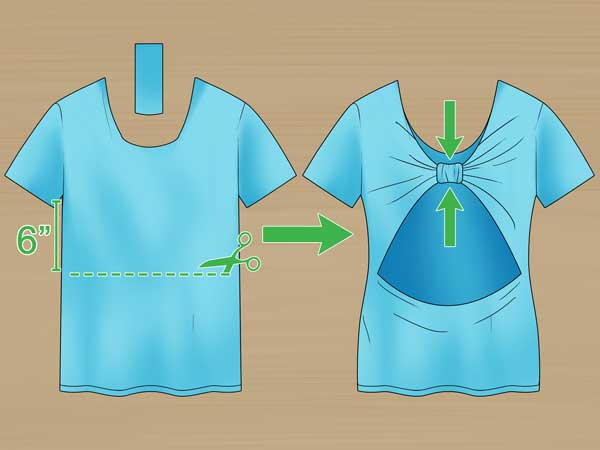

Before cutting the fabric, a design is made with dimensions, size, and stylistic preferences.

Image Source: WikiHow

When the design is done, the t-shirt is cut following the dimensions and pattern. 15% of the fabric are cut down to create the blank garment. Each garment has a front and back section, sleeves, pockets (not in all cases), and trim.

Assembling

This stage deals with the parts that I just mentioned. At first, both separate pieces of front and back sections are stitched at the sides. Untubed pieces form a narrow and superimposed seam and are stitched together through an overedge stitch.

Then comes the sleeves. Both the sleeves are normally formed before stitching them into the garment. In the same t-shirts, the edge is folded over through hem and stitch. Some manufacturers apply a band as a superimposed seam.

For tubular-shaped t-shirts, the sleeves are sewn at first and stitched into the garments. If the manufacturer follows the 'cut and sewn' technique, then both the sleeves and the front and back sections seam are sewn at a time.

For a flexible hem, the garment is sewn with an overedge stitch. As the tension of stitching is loose enough, it doesn't cause tearing in the garment.

Some casual t-shirts include pockets. Premium quality t-shirt manufacturers insert an interlining into the pockets to maintain the shape. The pocket is sewn onto the front side of the t-shirt.

Pockets are also attached by automated setters. In this case, the manufacturer only needs to arrange the fabric and the setter; the machine takes care of stitching and seaming.

When it comes to shoulder seams, it requires a simple and superimposed seam. Premium t-shirt manufacturers enforce seams using elastic or tape. Shoulders are done before or after attaching the neckband, depending on the style of the t-shirt.

For example, when the tubular neckband needs to apply, the shoulder should be done first.

Attaching Neckband

The circumference of the outer neck edge is slightly shorter for crew neck shirts. Tubular neckbands are made manually.

Bound seams got a cover stitch, and it's pretty easy. The fabric needs to go through the machine where it gets folded and then applied tension to it.

Neckbands on lower-priced shirts are stitched separately on both sides. It makes the shoulder seams visible on the neckband.

V-neck t-shirts have either mitering or lapping neckband, which requires to fold one side over the other. Doing mitered seam is a bit difficult as it needs an operator to overlap accurately while stitching the band at the center.

Thus, the easiest way to handle a V-neck t-shirt is to attach the band to its neckline and sew the tuck right way; it will form a V neck.

Finishing the Neckline

To give the finishing touch to the neckline, superimposed seams are taped to make the shirt even stronger and comfortable. The tape is extended over the shoulder and across the back seams for reinforcing the area to flatten the seam.

Labeling

In most shirts, there are one or two labels attached at the back. Neckline labels contain information about size, fabric content, washing instructions, and the manufacturer itself.

Transforming into the Print

Then comes the decorative works. The customer finalizes the design that includes colors, ink type, sizing, and placement. Everything about the design is printed onto a clear film.

Screen Printing

The transparent films expose the image or design onto the mesh screen that is sensitive to photo emulsion. A vacuum-sealed UV light table is there to expose the screens. Later on, by rinsing with water, the design is checked for accuracy.

At this stage, the screen is placed on an automated screen press for printing the image or design to shirts.

Finishing Operations

At the last stage of production, the shirts are inspected to find any flaw in the fabric, thread, and stitching. Premium quality shirts go through steam tunnels before packaging. T-shirts are folded around a piece of cardboard that maintains the shape while shipping.

Quality Control

Federal and international guidelines regulate manufacturing clothing operations. There might be some internal guidelines from the manufacturer as well. Maintaining quality standards is a must within the industry.

Quality control ensures proper sizing, fitting, appropriate and standard needles, seams, stitches, numbers of stitches per inch, etc. The stitches should be loose enough that allows the garment to stretch without tearing up the seams. Hems need to be flattened and wide to prevent curling.

Besides, the shirts are further inspected for proper necklines application to ensure that it rests flat against the body. The neckline should be able to recover if it's slightly stretched.

100% Cotton Vs. Polyester Blends

There is an overwhelming conversation in the textile manufacturing industry when it comes to talking about 100% cotton vs. polyester blends. Both differ from each other in various aspects. Let's have a look at which one dominates over the other.

Comfortability

100% cotton made clothing is soft and gentle on the skin. Although pure cotton feels heavier than cotton blended garments, it has a finer drape, unique smoothness, and excellent breathability.

Blended fabrics, on the flip side, cause skin irritation and aggravate allergens and disorders.

Durability

When it's about durability, the cotton-polyester blend takes the lead here. Blended fabrics are stronger than pure cotton ones.

Printability

As pure cotton garments aren't that much sensitive to dye migration like blended ones, it's easy to print on them. It holds the ink easily and ensures the design looks absolutely stunning. 100% cotton garments are an excellent choice when it comes to digital four-color printing.

For the digital sublimation process, pure cotton isn't that good as blended fabrics.

Affordability

Considering affordability, polyester is cheaper than cotton. So, a 50/50 cotton blend is a good deal when it comes to compromising with the price of cotton.

Eco-Friendly

Organic cotton farmers don't require buying a large number of pesticides. Thus, manufacturing organic cotton products don't contribute to landfills, and they are recyclable as well.

Expert Tips for Maintaining 100% Cotton T-shirts

Cotton is a natural fiber that is strong and durable, making it an ideal material for t-shirts. However, cotton shirts can be susceptible to shrinking and wrinkling if they are not properly cared for. Here are some expert tips for keeping your 100% cotton t-shirt looking its best:

- Wash your shirt in cold water. Hot water can cause the fabric to shrink.

- Hang your shirt up to dry. Don't put it in the dryer, as this will also cause shrinkage.

- Iron your shirt on low heat. If you use too much heat, you risk damaging the fabric.

- When storing your shirt, fold it rather than hanging it up. This will help prevent wrinkles.

By following these simple tips, you can keep your 100% cotton t-shirt looking new for years to come!

Conclusion

Cotton is a name of comfort for most customers out there. The clothing feels soft and very comfortable to wear. Lots of manufacturers produce apparel using organic cotton, which is a great deal if you are an environmentalist.

|

|

|

|

|

|

|

|

About Alice Davis

Alice is a writer who lives in the City of Long Beach. She has a husband, an exceptionally small chihuahua, and 15-pound Maine Coon. Alice got her bachelor of science in biological science from UC Berkeley. Now, she likes writing about a lot of things; including but not limited to technology reviews, science stuff, and anything food-related.

Leave a Reply

You can get FREE Gifts. Or latest Free phones here.

Disable Ad block to reveal all the info. Once done, hit a button below

|

|

|

|